The bolt is a common mechanical part, often used in many places. It is the head and the screw, two parts of the composition of a class of fasteners, which must be used in conjunction with the nut, mainly to secure the connection of two parts with a through hole. Perhaps you have no idea about the quality of the bolt material, this article will introduce you to bolt material, quality knowledge, so that more people can learn to identify these small properties of the bolt.

What do the qualities and materials of the bolts refer to?

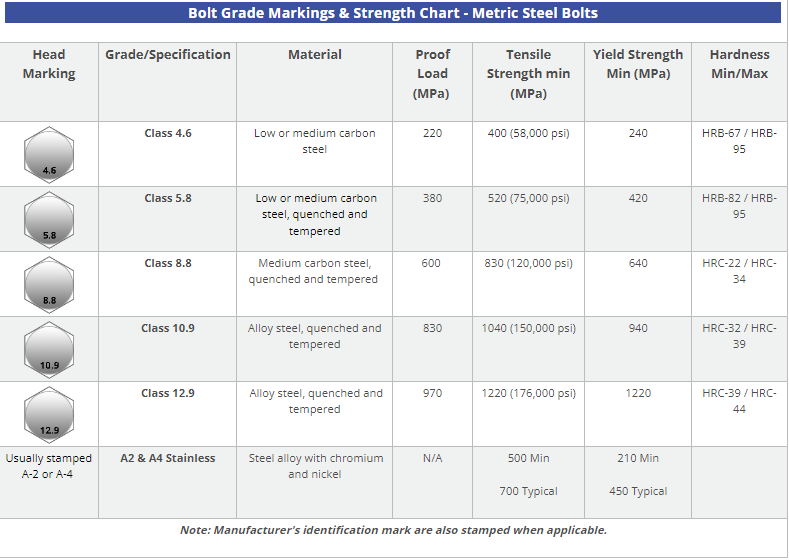

The bolt quality corresponds to 4.8, 8.8, 10.9 and other bolt qualities.

The material used to manufacture the bolt is Q235, 35K, 40Cr, 45 # steel, 35CrMo steel, 304 stainless steel and 316 stainless steel, etc.

Mild steel can only produce low strength bolts, medium carbon steel can produce medium strength bolts, high carbon steel and alloy steel can produce high strength bolts. Some bolt grades specify the chemical composition and corresponding mechanical properties, but also identify the material.

Here is a list of common bolt grades, depending on the material used. Grade 4.8 can be Q235, Q195 and other mild steel materials. Grade 5.8, Q235, can be used for all materials and does not require heat treatment. Level 8.8, thread diameter 16 mm or less, 35 #, heat treated, 16 mm or more, 45 # and low carbon alloy steel, heat treated. Level 10.9, medium carbon alloy steel, heat treatment. Heat treatment 35Crmo 40Cr, etc.

Can high-strength bolts be distinguished from ordinary bolts by their material?

Bolts are generally divided according to their degree of strength.

Bolt performance level 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9 and so on, more than 10 grades, including bolts 8.8 and above made of low-carbon alloy steel or medium-carbon steel and heat-treated (hardened, tempered), commonly known as high-strength bolts, the other bolts being commonly known as ordinary bolts. The bolt performance level marking comprises two parts of numerical composition, respectively the nominal tensile strength of the bolt material and the value of the bending strength ratio.

For example, the performance level of class 8.8 bolts is as follows

1, the nominal tensile strength of the bolt material is 800MPa ;

2, the yield strength ratio of the bolt material is 0.8 ;

3, the nominal yield strength of the bolt material is 800 × 0.8 = 640MPa. The most commonly used high-strength bolts are grade 8.8 and 10.9, and the most commonly used ordinary bolts are grade 4.8.

How can you tell the difference between high-strength bolts and ordinary bolts?

Carbon steel materials are divided into high-strength and ordinary materials. Carbon steel bolts produced from high-strength materials are called high-strength bolts. For example, we use 45# steel to produce double head bolts, and for example, we use 35k steel to produce hexagonal bolts and hexagonal bolts, these bolts are casted, there will be a heat treatment process, after completion, the level of the bolt reaches class 8.8, although the same carbon steel material, but due to the improved performance level, that’s why they are called high strength bolts. For example, we use 40Crmo alloy steel to produce 10.9 hex bolts, and for example, we use 35Crmo alloy steel to produce 12.9 bolts, etc., these levels are higher than the 8.8 level, so they are called high-strength bolts.

Bolts produced with ordinary carbon steel materials are called ordinary bolts. For example, we use Q235 material to produce 4.8 hexagonal bolts, like our A3 steel material to produce 4 hexagonal nuts, etc., these materials after completion of production only require surface cleaning or electro-galvanised surface treatment, and do not require heat treatment, so they are called ordinary bolts.

From the above, we can establish a law: so-called high-strength bolts, i.e. those with mechanical properties equal to or greater than 8.8 and which require heat treatment, are called high-strength bolts. Bolts with mechanical properties below 8.8 are called ordinary bolts, with a strength of 4.8, which do not require heat treatment.

Post time: Aug-30-2024