Hexagon Bolts are created to DIN 931

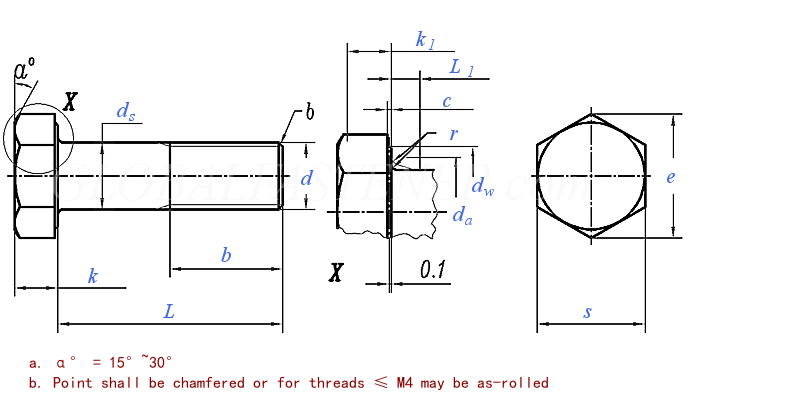

| Products name | HEX BOLT DIN 931/ISO4014 half thread |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Grade | Steel Grade: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A,A325,A490, |

| Finishing | Zinc(Yellow,White,Blue,Black),Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated |

| Production Process | M2-M24:Cold Froging,M24-M100 Hot Forging, Machining and CNC for Customized fastener |

| Customized Products Lead time | 30-60days, |

|

Screw Thread |

M1.6 |

M2 |

M2.5 |

M3 |

(M3.5) |

M4 |

M5 |

M6 |

(M7) |

M8 |

M10 |

M12 |

||

|

P |

Pitch |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

1.25 |

1.5 |

1.75 |

|

|

b |

L≤125 |

9 |

10 |

11 |

12 |

13 |

14 |

16 |

18 |

20 |

22 |

26 |

30 |

|

|

125<L≤200 |

15 |

16 |

17 |

18 |

19 |

20 |

22 |

24 |

26 |

28 |

32 |

36 |

||

|

L>200 |

28 |

29 |

30 |

31 |

32 |

33 |

35 |

37 |

39 |

41 |

45 |

49 |

||

|

c |

max |

0.25 |

0.25 |

0.25 |

0.4 |

0.4 |

0.4 |

0.5 |

0.5 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

min |

0.1 |

0.1 |

0.1 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

||

|

da |

max |

2 |

2.6 |

3.1 |

3.6 |

4.1 |

4.7 |

5.7 |

6.8 |

7.8 |

9.2 |

11.2 |

13.7 |

|

|

ds |

max=nominal size |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

7 |

8 |

10 |

12 |

|

|

Grade A |

min |

1.46 |

1.86 |

2.36 |

2.86 |

3.32 |

3.82 |

4.82 |

5.82 |

6.78 |

7.78 |

9.78 |

11.73 |

|

|

Grade B |

min |

1.35 |

1.75 |

2.25 |

2.75 |

3.2 |

3.7 |

4.7 |

5.7 |

6.64 |

7.64 |

9.64 |

11.57 |

|

|

dw |

Grade A |

min |

2.54 |

3.34 |

4.34 |

4.84 |

5.34 |

6.2 |

7.2 |

8.88 |

9.63 |

11.63 |

14.63 |

16.63 |

|

Grade B |

min |

2.42 |

3.22 |

4.22 |

4.72 |

5.22 |

6.06 |

7.06 |

8.74 |

9.47 |

11.47 |

14.47 |

16.47 |

|

|

e |

Grade A |

min |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

14.38 |

17.77 |

20.03 |

|

Grade B |

min |

3.28 |

4.18 |

5.31 |

5.88 |

6.44 |

7.5 |

8.63 |

10.89 |

11.94 |

14.2 |

17.59 |

19.85 |

|

|

L1 |

max |

0.6 |

0.8 |

1 |

1 |

1 |

1.2 |

1.2 |

1.4 |

1.4 |

2 |

2 |

3 |

|

|

k |

Nominal Size |

1.1 |

1.4 |

1.7 |

2 |

2.4 |

2.8 |

3.5 |

4 |

4.8 |

5.3 |

6.4 |

7.5 |

|

|

Grade A |

max |

1.225 |

1.525 |

1.825 |

2.125 |

2.525 |

2.925 |

3.65 |

4.15 |

4.95 |

5.45 |

6.58 |

7.68 |

|

|

min |

0.975 |

1.275 |

1.575 |

1.875 |

2.275 |

2.675 |

3.35 |

3.85 |

4.65 |

5.15 |

6.22 |

7.32 |

||

|

Grade B |

max |

1.3 |

1.6 |

1.9 |

2.2 |

2.6 |

3 |

3.74 |

4.24 |

5.04 |

5.54 |

6.69 |

7.79 |

|

|

min |

0.9 |

1.2 |

1.5 |

1.8 |

2.2 |

2.6 |

3.26 |

3.76 |

4.56 |

5.06 |

6.11 |

7.21 |

||

|

k1 |

Grade A |

min |

0.68 |

0.89 |

1.1 |

1.31 |

1.59 |

1.87 |

2.35 |

2.7 |

3.26 |

3.61 |

4.35 |

5.12 |

|

Grade B |

min |

0.63 |

0.84 |

1.05 |

1.26 |

1.54 |

1.82 |

2.28 |

2.63 |

3.19 |

3.54 |

4.28 |

5.05 |

|

|

r |

min |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.2 |

0.2 |

0.25 |

0.25 |

0.4 |

0.4 |

0.6 |

|

|

s |

max=nominal size |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

13 |

16 |

18 |

|

|

Grade A |

min |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

12.73 |

15.73 |

17.73 |

|

|

Grade B |

min |

2.9 |

3.7 |

4.7 |

5.2 |

5.7 |

6.64 |

7.64 |

9.64 |

10.57 |

12.57 |

15.57 |

17.57 |

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||

|

Screw Thread |

(M14) |

M16 |

(M18) |

M20 |

(M22) |

M24 |

(M27) |

M30 |

(M33) |

M36 |

(M39) |

M42 |

||

|

P |

Pitch |

2 |

2 |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

|

|

b |

L≤125 |

34 |

38 |

42 |

46 |

50 |

54 |

60 |

66 |

72 |

- |

- |

- |

|

|

125<L≤200 |

40 |

44 |

48 |

52 |

56 |

60 |

66 |

72 |

78 |

84 |

90 |

96 |

||

|

L>200 |

53 |

57 |

61 |

65 |

69 |

73 |

79 |

85 |

91 |

97 |

103 |

109 |

||

|

c |

max |

0.6 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

1 |

1 |

|

|

min |

0.15 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.3 |

0.3 |

||

|

da |

max |

15.7 |

17.7 |

20.2 |

22.4 |

24.4 |

26.4 |

30.4 |

33.4 |

36.4 |

39.4 |

42.4 |

45.6 |

|

|

ds |

max=nominal size |

14 |

16 |

18 |

20 |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

42 |

|

|

Grade A |

min |

13.73 |

15.73 |

17.73 |

19.67 |

21.67 |

23.67 |

- |

- |

- |

- |

- |

- |

|

|

Grade B |

min |

13.57 |

15.57 |

17.57 |

19.48 |

21.48 |

23.48 |

26.48 |

29.48 |

32.38 |

35.38 |

38.38 |

41.38 |

|

|

dw |

Grade A |

min |

19.64 |

22.49 |

25.34 |

28.19 |

31.71 |

33.61 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

19.15 |

22 |

24.85 |

27.7 |

31.35 |

33.25 |

38 |

42.75 |

46.55 |

51.11 |

55.86 |

59.95 |

|

|

e |

Grade A |

min |

23.36 |

26.75 |

30.14 |

33.53 |

37.72 |

39.98 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

22.78 |

26.17 |

29.56 |

32.95 |

37.29 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

|

|

L1 |

max |

3 |

3 |

3 |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

6 |

8 |

|

|

k |

Nominal Size |

8.8 |

10 |

11.5 |

12.5 |

14 |

15 |

17 |

18.7 |

21 |

22.5 |

25 |

26 |

|

|

Grade A |

max |

8.98 |

10.18 |

11.715 |

12.715 |

14.215 |

15.215 |

- |

- |

- |

- |

- |

- |

|

|

min |

8.62 |

9.82 |

11.285 |

12.285 |

13.785 |

14.785 |

- |

- |

- |

- |

- |

- |

||

|

Grade B |

max |

9.09 |

10.29 |

11.85 |

12.85 |

14.35 |

15.35 |

17.35 |

19.12 |

21.42 |

22.92 |

25.42 |

26.42 |

|

|

min |

8.51 |

9.71 |

11.15 |

12.15 |

13.65 |

14.65 |

16.65 |

18.28 |

20.58 |

22.08 |

24.58 |

25.58 |

||

|

k1 |

Grade A |

min |

6.03 |

6.87 |

7.9 |

8.6 |

9.65 |

10.35 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

5.96 |

6.8 |

7.81 |

8.51 |

9.56 |

10.26 |

11.66 |

12.8 |

14.41 |

15.46 |

17.21 |

17.91 |

|

|

r |

min |

0.6 |

0.6 |

0.6 |

0.8 |

0.8 |

0.8 |

1 |

1 |

1 |

1 |

1 |

1.2 |

|

|

s |

max=nominal size |

21 |

24 |

27 |

30 |

34 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

|

|

Grade A |

min |

20.67 |

23.67 |

26.67 |

29.67 |

33.38 |

35.38 |

- |

- |

- |

- |

- |

- |

|

|

Grade B |

min |

20.16 |

23.16 |

26.16 |

29.16 |

33 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.1 |

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

||

|

Screw Thread |

(M45) |

M48 |

(M52) |

M56 |

(M60) |

M64 |

|

|

|

|

|

|

||

|

P |

Pitch |

4.5 |

5 |

5 |

5.5 |

5.5 |

6 |

|

|

|

|

|

|

|

|

b |

L≤125 |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

125<L≤200 |

102 |

108 |

116 |

- |

- |

- |

|

|

|

|

|

|

||

|

L>200 |

115 |

121 |

129 |

137 |

145 |

153 |

|

|

|

|

|

|

||

|

c |

max |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

min |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|

|

|

|

|

|

||

|

da |

max |

48.6 |

52.6 |

56.6 |

63 |

67 |

71 |

|

|

|

|

|

|

|

|

ds |

max=nominal size |

45 |

48 |

52 |

56 |

60 |

64 |

|

|

|

|

|

|

|

|

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Grade B |

min |

44.38 |

47.38 |

51.26 |

55.26 |

59.26 |

63.26 |

|

|

|

|

|

|

|

|

dw |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

64.7 |

69.45 |

74.2 |

78.66 |

83.41 |

88.16 |

|

|

|

|

|

|

|

|

e |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

76.95 |

82.6 |

88.25 |

93.56 |

99.21 |

104.86 |

|

|

|

|

|

|

|

|

L1 |

max |

8 |

10 |

10 |

12 |

12 |

13 |

|

|

|

|

|

|

|

|

k |

Nominal Size |

28 |

30 |

33 |

35 |

38 |

40 |

|

|

|

|

|

|

|

|

Grade A |

max |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

||

|

Grade B |

max |

28.42 |

30.42 |

33.5 |

35.5 |

38.5 |

40.5 |

|

|

|

|

|

|

|

|

min |

27.58 |

29.58 |

32.5 |

34.5 |

37.5 |

39.5 |

|

|

|

|

|

|

||

|

k1 |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

19.31 |

20.71 |

22.75 |

24.15 |

26.25 |

27.65 |

|

|

|

|

|

|

|

|

r |

min |

1.2 |

1.6 |

1.6 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

s |

max=nominal size |

70 |

75 |

80 |

85 |

90 |

95 |

|

|

|

|

|

|

|

|

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Grade B |

min |

68.1 |

73.1 |

78.1 |

82.8 |

87.8 |

92.8 |

|

|

|

|

|

|

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|||

Features and Benefits

Hexagon bolts are a type of fastener that is designed with a six-sided head and a partially threaded shaft. DIN 931 is a technical standard that outlines the manufacturing requirements for hexagon bolts. These bolts are commonly used in various industrial and mechanical applications due to their strength, durability, and versatility.

One of the key features of hexagon bolts created to DIN 931 is their partial threading. Unlike fully threaded bolts, which have threads that run the entire length of the shaft, hexagon bolts only have threads on a portion of their length. This design allows the bolt to be securely fastened in place while still providing enough clearance for components to move when necessary.

Another important aspect of hexagon bolts is their six-sided head. This design offers several advantages over other types of bolts. Firstly, the hexagonal shape allows for easier tightening and loosening with a wrench or socket. Secondly, the larger surface area of the head distributes the force of tightening over a wider area, reducing the likelihood of damage or deformation.

Hexagon bolts created to DIN 931 are available in a wide range of sizes and materials, making them suitable for a vast array of applications. They are commonly used in construction, automotive, and industrial machinery, as well as in household and DIY projects. The combination of their strength, durability, and ease of use makes hexagon bolts an essential component in many types of machinery and equipment.

In summary, hexagon bolts created to DIN 931 are designed to provide a secure and reliable fastening solution for a variety of applications. Their partially threaded shaft and six-sided head offer a range of benefits, including ease of use, increased strength and durability, and versatility. These bolts are an essential part of many types of machinery and equipment, and their popularity is a testament to their quality and effectiveness.