hex Bolt Din 931 / iso4014 933 / iso4017 Black

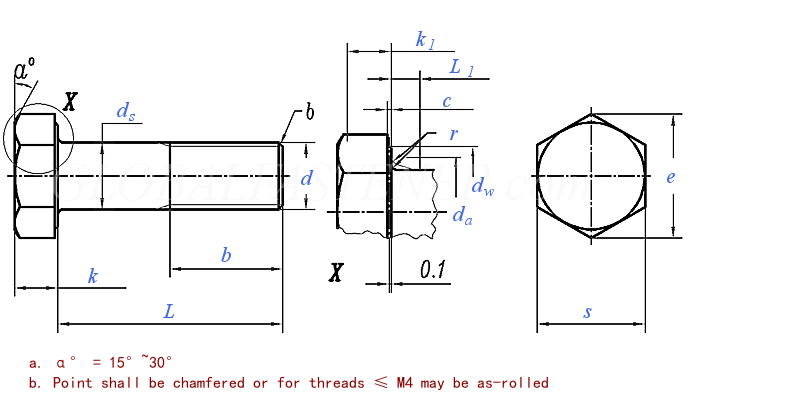

| Products name | HEX BOLT DIN 931/ISO4014 half thread |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Grade | Steel Grade: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A,A325,A490, |

| Finishing | Zinc(Yellow,White,Blue,Black),Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated |

| Production Process | M2-M24:Cold Froging,M24-M100 Hot Forging, Machining and CNC for Customized fastener |

| Customized Products Lead time | 30-60days, |

|

Screw Thread |

M1.6 |

M2 |

M2.5 |

M3 |

(M3.5) |

M4 |

M5 |

M6 |

(M7) |

M8 |

M10 |

M12 |

||

|

P |

Pitch |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

1.25 |

1.5 |

1.75 |

|

|

b |

L≤125 |

9 |

10 |

11 |

12 |

13 |

14 |

16 |

18 |

20 |

22 |

26 |

30 |

|

|

125<L≤200 |

15 |

16 |

17 |

18 |

19 |

20 |

22 |

24 |

26 |

28 |

32 |

36 |

||

|

L>200 |

28 |

29 |

30 |

31 |

32 |

33 |

35 |

37 |

39 |

41 |

45 |

49 |

||

|

c |

max |

0.25 |

0.25 |

0.25 |

0.4 |

0.4 |

0.4 |

0.5 |

0.5 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

min |

0.1 |

0.1 |

0.1 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

||

|

da |

max |

2 |

2.6 |

3.1 |

3.6 |

4.1 |

4.7 |

5.7 |

6.8 |

7.8 |

9.2 |

11.2 |

13.7 |

|

|

ds |

max=nominal size |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

7 |

8 |

10 |

12 |

|

|

Grade A |

min |

1.46 |

1.86 |

2.36 |

2.86 |

3.32 |

3.82 |

4.82 |

5.82 |

6.78 |

7.78 |

9.78 |

11.73 |

|

|

Grade B |

min |

1.35 |

1.75 |

2.25 |

2.75 |

3.2 |

3.7 |

4.7 |

5.7 |

6.64 |

7.64 |

9.64 |

11.57 |

|

|

dw |

Grade A |

min |

2.54 |

3.34 |

4.34 |

4.84 |

5.34 |

6.2 |

7.2 |

8.88 |

9.63 |

11.63 |

14.63 |

16.63 |

|

Grade B |

min |

2.42 |

3.22 |

4.22 |

4.72 |

5.22 |

6.06 |

7.06 |

8.74 |

9.47 |

11.47 |

14.47 |

16.47 |

|

|

e |

Grade A |

min |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

14.38 |

17.77 |

20.03 |

|

Grade B |

min |

3.28 |

4.18 |

5.31 |

5.88 |

6.44 |

7.5 |

8.63 |

10.89 |

11.94 |

14.2 |

17.59 |

19.85 |

|

|

L1 |

max |

0.6 |

0.8 |

1 |

1 |

1 |

1.2 |

1.2 |

1.4 |

1.4 |

2 |

2 |

3 |

|

|

k |

Nominal Size |

1.1 |

1.4 |

1.7 |

2 |

2.4 |

2.8 |

3.5 |

4 |

4.8 |

5.3 |

6.4 |

7.5 |

|

|

Grade A |

max |

1.225 |

1.525 |

1.825 |

2.125 |

2.525 |

2.925 |

3.65 |

4.15 |

4.95 |

5.45 |

6.58 |

7.68 |

|

|

min |

0.975 |

1.275 |

1.575 |

1.875 |

2.275 |

2.675 |

3.35 |

3.85 |

4.65 |

5.15 |

6.22 |

7.32 |

||

|

Grade B |

max |

1.3 |

1.6 |

1.9 |

2.2 |

2.6 |

3 |

3.74 |

4.24 |

5.04 |

5.54 |

6.69 |

7.79 |

|

|

min |

0.9 |

1.2 |

1.5 |

1.8 |

2.2 |

2.6 |

3.26 |

3.76 |

4.56 |

5.06 |

6.11 |

7.21 |

||

|

k1 |

Grade A |

min |

0.68 |

0.89 |

1.1 |

1.31 |

1.59 |

1.87 |

2.35 |

2.7 |

3.26 |

3.61 |

4.35 |

5.12 |

|

Grade B |

min |

0.63 |

0.84 |

1.05 |

1.26 |

1.54 |

1.82 |

2.28 |

2.63 |

3.19 |

3.54 |

4.28 |

5.05 |

|

|

r |

min |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.2 |

0.2 |

0.25 |

0.25 |

0.4 |

0.4 |

0.6 |

|

|

s |

max=nominal size |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

13 |

16 |

18 |

|

|

Grade A |

min |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

12.73 |

15.73 |

17.73 |

|

|

Grade B |

min |

2.9 |

3.7 |

4.7 |

5.2 |

5.7 |

6.64 |

7.64 |

9.64 |

10.57 |

12.57 |

15.57 |

17.57 |

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||

|

Screw Thread |

(M14) |

M16 |

(M18) |

M20 |

(M22) |

M24 |

(M27) |

M30 |

(M33) |

M36 |

(M39) |

M42 |

||

|

P |

Pitch |

2 |

2 |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

|

|

b |

L≤125 |

34 |

38 |

42 |

46 |

50 |

54 |

60 |

66 |

72 |

- |

- |

- |

|

|

125<L≤200 |

40 |

44 |

48 |

52 |

56 |

60 |

66 |

72 |

78 |

84 |

90 |

96 |

||

|

L>200 |

53 |

57 |

61 |

65 |

69 |

73 |

79 |

85 |

91 |

97 |

103 |

109 |

||

|

c |

max |

0.6 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

1 |

1 |

|

|

min |

0.15 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.3 |

0.3 |

||

|

da |

max |

15.7 |

17.7 |

20.2 |

22.4 |

24.4 |

26.4 |

30.4 |

33.4 |

36.4 |

39.4 |

42.4 |

45.6 |

|

|

ds |

max=nominal size |

14 |

16 |

18 |

20 |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

42 |

|

|

Grade A |

min |

13.73 |

15.73 |

17.73 |

19.67 |

21.67 |

23.67 |

- |

- |

- |

- |

- |

- |

|

|

Grade B |

min |

13.57 |

15.57 |

17.57 |

19.48 |

21.48 |

23.48 |

26.48 |

29.48 |

32.38 |

35.38 |

38.38 |

41.38 |

|

|

dw |

Grade A |

min |

19.64 |

22.49 |

25.34 |

28.19 |

31.71 |

33.61 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

19.15 |

22 |

24.85 |

27.7 |

31.35 |

33.25 |

38 |

42.75 |

46.55 |

51.11 |

55.86 |

59.95 |

|

|

e |

Grade A |

min |

23.36 |

26.75 |

30.14 |

33.53 |

37.72 |

39.98 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

22.78 |

26.17 |

29.56 |

32.95 |

37.29 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

|

|

L1 |

max |

3 |

3 |

3 |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

6 |

8 |

|

|

k |

Nominal Size |

8.8 |

10 |

11.5 |

12.5 |

14 |

15 |

17 |

18.7 |

21 |

22.5 |

25 |

26 |

|

|

Grade A |

max |

8.98 |

10.18 |

11.715 |

12.715 |

14.215 |

15.215 |

- |

- |

- |

- |

- |

- |

|

|

min |

8.62 |

9.82 |

11.285 |

12.285 |

13.785 |

14.785 |

- |

- |

- |

- |

- |

- |

||

|

Grade B |

max |

9.09 |

10.29 |

11.85 |

12.85 |

14.35 |

15.35 |

17.35 |

19.12 |

21.42 |

22.92 |

25.42 |

26.42 |

|

|

min |

8.51 |

9.71 |

11.15 |

12.15 |

13.65 |

14.65 |

16.65 |

18.28 |

20.58 |

22.08 |

24.58 |

25.58 |

||

|

k1 |

Grade A |

min |

6.03 |

6.87 |

7.9 |

8.6 |

9.65 |

10.35 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

5.96 |

6.8 |

7.81 |

8.51 |

9.56 |

10.26 |

11.66 |

12.8 |

14.41 |

15.46 |

17.21 |

17.91 |

|

|

r |

min |

0.6 |

0.6 |

0.6 |

0.8 |

0.8 |

0.8 |

1 |

1 |

1 |

1 |

1 |

1.2 |

|

|

s |

max=nominal size |

21 |

24 |

27 |

30 |

34 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

|

|

Grade A |

min |

20.67 |

23.67 |

26.67 |

29.67 |

33.38 |

35.38 |

- |

- |

- |

- |

- |

- |

|

|

Grade B |

min |

20.16 |

23.16 |

26.16 |

29.16 |

33 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.1 |

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

||

|

Screw Thread |

(M45) |

M48 |

(M52) |

M56 |

(M60) |

M64 |

|

|

|

|

|

|

||

|

P |

Pitch |

4.5 |

5 |

5 |

5.5 |

5.5 |

6 |

|

|

|

|

|

|

|

|

b |

L≤125 |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

125<L≤200 |

102 |

108 |

116 |

- |

- |

- |

|

|

|

|

|

|

||

|

L>200 |

115 |

121 |

129 |

137 |

145 |

153 |

|

|

|

|

|

|

||

|

c |

max |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

min |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|

|

|

|

|

|

||

|

da |

max |

48.6 |

52.6 |

56.6 |

63 |

67 |

71 |

|

|

|

|

|

|

|

|

ds |

max=nominal size |

45 |

48 |

52 |

56 |

60 |

64 |

|

|

|

|

|

|

|

|

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Grade B |

min |

44.38 |

47.38 |

51.26 |

55.26 |

59.26 |

63.26 |

|

|

|

|

|

|

|

|

dw |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

64.7 |

69.45 |

74.2 |

78.66 |

83.41 |

88.16 |

|

|

|

|

|

|

|

|

e |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

76.95 |

82.6 |

88.25 |

93.56 |

99.21 |

104.86 |

|

|

|

|

|

|

|

|

L1 |

max |

8 |

10 |

10 |

12 |

12 |

13 |

|

|

|

|

|

|

|

|

k |

Nominal Size |

28 |

30 |

33 |

35 |

38 |

40 |

|

|

|

|

|

|

|

|

Grade A |

max |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

||

|

Grade B |

max |

28.42 |

30.42 |

33.5 |

35.5 |

38.5 |

40.5 |

|

|

|

|

|

|

|

|

min |

27.58 |

29.58 |

32.5 |

34.5 |

37.5 |

39.5 |

|

|

|

|

|

|

||

|

k1 |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

19.31 |

20.71 |

22.75 |

24.15 |

26.25 |

27.65 |

|

|

|

|

|

|

|

|

r |

min |

1.2 |

1.6 |

1.6 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

s |

max=nominal size |

70 |

75 |

80 |

85 |

90 |

95 |

|

|

|

|

|

|

|

|

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Grade B |

min |

68.1 |

73.1 |

78.1 |

82.8 |

87.8 |

92.8 |

|

|

|

|

|

|

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|||

Features and Benefits

Hex Bolt Din 931 / ISO4014 933 / ISO4017 Black: The Industrial Giant

Black is a color that carries with it a certain appeal and sense of perfection. It represents power, strength, and authority. It is no wonder, then, that it is a common finish for fasteners in industrial applications. The hex bolt Din 931 / ISO4014 933 / ISO4017 black is particularly popular in the construction and automotive industries.

Hex bolts are a type of fastener that is designed to be used with a nut or in a tapped hole. They feature a six-sided head that can be tightened or loosened with a wrench. The Din 931, ISO4014 933, and ISO4017 are all slightly different variations of the hex bolt, with different standards implemented regarding size and other factors.

One of the most notable characteristics of the hex bolt Din 931 / ISO4014 933 / ISO4017 black is its corrosion resistance. The black finish is typically achieved through black oxide coating, which is a process that involves oxidizing the steel to create a thin layer of black oxide. This layer not only gives the hex bolt its distinctive black color but also provides a protective layer against rust and other forms of corrosion.

Another advantage of the black finish on hex bolts is that it helps to reduce glare. This is particularly beneficial in applications where visibility is important, such as in automotive manufacturing or other outdoor settings. The black finish also gives hex bolts a sleek, professional look that is preferred by many industrial professionals.

In conclusion, the hex bolt Din 931 / ISO4014 933 / ISO4017 black is an industrial giant that boasts strength, durability, and corrosion resistance. Its black finish provides a number of benefits, including corrosion protection, reduced glare, and a professional appearance. All of these factors make the hex bolt Din 931 / ISO4014 933 / ISO4017 black an excellent choice for industrial applications where durability and aesthetics are both important.