DIN 6921 flange bolts Class 8.8 and 10.9

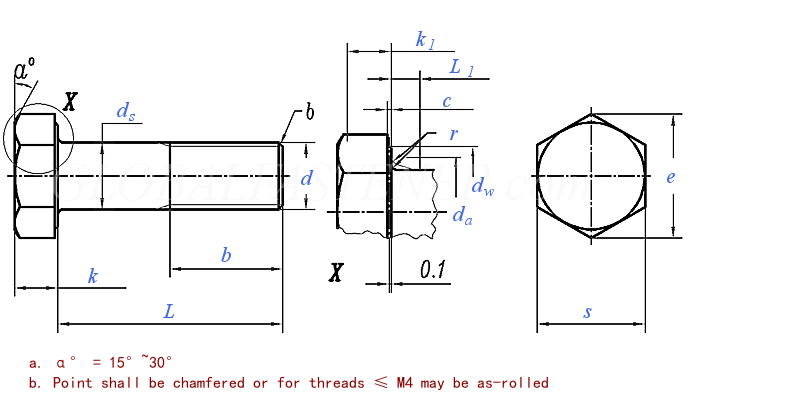

| Products name | HEX BOLT DIN 931/ISO4014 half thread |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Grade | Steel Grade: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A,A325,A490, |

| Finishing | Zinc(Yellow,White,Blue,Black),Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated |

| Production Process | M2-M24:Cold Froging,M24-M100 Hot Forging, Machining and CNC for Customized fastener |

| Customized Products Lead time | 30-60days, |

|

Screw Thread |

M1.6 |

M2 |

M2.5 |

M3 |

(M3.5) |

M4 |

M5 |

M6 |

(M7) |

M8 |

M10 |

M12 |

||

|

P |

Pitch |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

1.25 |

1.5 |

1.75 |

|

|

b |

L≤125 |

9 |

10 |

11 |

12 |

13 |

14 |

16 |

18 |

20 |

22 |

26 |

30 |

|

|

125<L≤200 |

15 |

16 |

17 |

18 |

19 |

20 |

22 |

24 |

26 |

28 |

32 |

36 |

||

|

L>200 |

28 |

29 |

30 |

31 |

32 |

33 |

35 |

37 |

39 |

41 |

45 |

49 |

||

|

c |

max |

0.25 |

0.25 |

0.25 |

0.4 |

0.4 |

0.4 |

0.5 |

0.5 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

min |

0.1 |

0.1 |

0.1 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

||

|

da |

max |

2 |

2.6 |

3.1 |

3.6 |

4.1 |

4.7 |

5.7 |

6.8 |

7.8 |

9.2 |

11.2 |

13.7 |

|

|

ds |

max=nominal size |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

7 |

8 |

10 |

12 |

|

|

Grade A |

min |

1.46 |

1.86 |

2.36 |

2.86 |

3.32 |

3.82 |

4.82 |

5.82 |

6.78 |

7.78 |

9.78 |

11.73 |

|

|

Grade B |

min |

1.35 |

1.75 |

2.25 |

2.75 |

3.2 |

3.7 |

4.7 |

5.7 |

6.64 |

7.64 |

9.64 |

11.57 |

|

|

dw |

Grade A |

min |

2.54 |

3.34 |

4.34 |

4.84 |

5.34 |

6.2 |

7.2 |

8.88 |

9.63 |

11.63 |

14.63 |

16.63 |

|

Grade B |

min |

2.42 |

3.22 |

4.22 |

4.72 |

5.22 |

6.06 |

7.06 |

8.74 |

9.47 |

11.47 |

14.47 |

16.47 |

|

|

e |

Grade A |

min |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

14.38 |

17.77 |

20.03 |

|

Grade B |

min |

3.28 |

4.18 |

5.31 |

5.88 |

6.44 |

7.5 |

8.63 |

10.89 |

11.94 |

14.2 |

17.59 |

19.85 |

|

|

L1 |

max |

0.6 |

0.8 |

1 |

1 |

1 |

1.2 |

1.2 |

1.4 |

1.4 |

2 |

2 |

3 |

|

|

k |

Nominal Size |

1.1 |

1.4 |

1.7 |

2 |

2.4 |

2.8 |

3.5 |

4 |

4.8 |

5.3 |

6.4 |

7.5 |

|

|

Grade A |

max |

1.225 |

1.525 |

1.825 |

2.125 |

2.525 |

2.925 |

3.65 |

4.15 |

4.95 |

5.45 |

6.58 |

7.68 |

|

|

min |

0.975 |

1.275 |

1.575 |

1.875 |

2.275 |

2.675 |

3.35 |

3.85 |

4.65 |

5.15 |

6.22 |

7.32 |

||

|

Grade B |

max |

1.3 |

1.6 |

1.9 |

2.2 |

2.6 |

3 |

3.74 |

4.24 |

5.04 |

5.54 |

6.69 |

7.79 |

|

|

min |

0.9 |

1.2 |

1.5 |

1.8 |

2.2 |

2.6 |

3.26 |

3.76 |

4.56 |

5.06 |

6.11 |

7.21 |

||

|

k1 |

Grade A |

min |

0.68 |

0.89 |

1.1 |

1.31 |

1.59 |

1.87 |

2.35 |

2.7 |

3.26 |

3.61 |

4.35 |

5.12 |

|

Grade B |

min |

0.63 |

0.84 |

1.05 |

1.26 |

1.54 |

1.82 |

2.28 |

2.63 |

3.19 |

3.54 |

4.28 |

5.05 |

|

|

r |

min |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.2 |

0.2 |

0.25 |

0.25 |

0.4 |

0.4 |

0.6 |

|

|

s |

max=nominal size |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

13 |

16 |

18 |

|

|

Grade A |

min |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

12.73 |

15.73 |

17.73 |

|

|

Grade B |

min |

2.9 |

3.7 |

4.7 |

5.2 |

5.7 |

6.64 |

7.64 |

9.64 |

10.57 |

12.57 |

15.57 |

17.57 |

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||

|

Screw Thread |

(M14) |

M16 |

(M18) |

M20 |

(M22) |

M24 |

(M27) |

M30 |

(M33) |

M36 |

(M39) |

M42 |

||

|

P |

Pitch |

2 |

2 |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

|

|

b |

L≤125 |

34 |

38 |

42 |

46 |

50 |

54 |

60 |

66 |

72 |

- |

- |

- |

|

|

125<L≤200 |

40 |

44 |

48 |

52 |

56 |

60 |

66 |

72 |

78 |

84 |

90 |

96 |

||

|

L>200 |

53 |

57 |

61 |

65 |

69 |

73 |

79 |

85 |

91 |

97 |

103 |

109 |

||

|

c |

max |

0.6 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

1 |

1 |

|

|

min |

0.15 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.3 |

0.3 |

||

|

da |

max |

15.7 |

17.7 |

20.2 |

22.4 |

24.4 |

26.4 |

30.4 |

33.4 |

36.4 |

39.4 |

42.4 |

45.6 |

|

|

ds |

max=nominal size |

14 |

16 |

18 |

20 |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

42 |

|

|

Grade A |

min |

13.73 |

15.73 |

17.73 |

19.67 |

21.67 |

23.67 |

- |

- |

- |

- |

- |

- |

|

|

Grade B |

min |

13.57 |

15.57 |

17.57 |

19.48 |

21.48 |

23.48 |

26.48 |

29.48 |

32.38 |

35.38 |

38.38 |

41.38 |

|

|

dw |

Grade A |

min |

19.64 |

22.49 |

25.34 |

28.19 |

31.71 |

33.61 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

19.15 |

22 |

24.85 |

27.7 |

31.35 |

33.25 |

38 |

42.75 |

46.55 |

51.11 |

55.86 |

59.95 |

|

|

e |

Grade A |

min |

23.36 |

26.75 |

30.14 |

33.53 |

37.72 |

39.98 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

22.78 |

26.17 |

29.56 |

32.95 |

37.29 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

|

|

L1 |

max |

3 |

3 |

3 |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

6 |

8 |

|

|

k |

Nominal Size |

8.8 |

10 |

11.5 |

12.5 |

14 |

15 |

17 |

18.7 |

21 |

22.5 |

25 |

26 |

|

|

Grade A |

max |

8.98 |

10.18 |

11.715 |

12.715 |

14.215 |

15.215 |

- |

- |

- |

- |

- |

- |

|

|

min |

8.62 |

9.82 |

11.285 |

12.285 |

13.785 |

14.785 |

- |

- |

- |

- |

- |

- |

||

|

Grade B |

max |

9.09 |

10.29 |

11.85 |

12.85 |

14.35 |

15.35 |

17.35 |

19.12 |

21.42 |

22.92 |

25.42 |

26.42 |

|

|

min |

8.51 |

9.71 |

11.15 |

12.15 |

13.65 |

14.65 |

16.65 |

18.28 |

20.58 |

22.08 |

24.58 |

25.58 |

||

|

k1 |

Grade A |

min |

6.03 |

6.87 |

7.9 |

8.6 |

9.65 |

10.35 |

- |

- |

- |

- |

- |

- |

|

Grade B |

min |

5.96 |

6.8 |

7.81 |

8.51 |

9.56 |

10.26 |

11.66 |

12.8 |

14.41 |

15.46 |

17.21 |

17.91 |

|

|

r |

min |

0.6 |

0.6 |

0.6 |

0.8 |

0.8 |

0.8 |

1 |

1 |

1 |

1 |

1 |

1.2 |

|

|

s |

max=nominal size |

21 |

24 |

27 |

30 |

34 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

|

|

Grade A |

min |

20.67 |

23.67 |

26.67 |

29.67 |

33.38 |

35.38 |

- |

- |

- |

- |

- |

- |

|

|

Grade B |

min |

20.16 |

23.16 |

26.16 |

29.16 |

33 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.1 |

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

||

|

Screw Thread |

(M45) |

M48 |

(M52) |

M56 |

(M60) |

M64 |

|

|

|

|

|

|

||

|

P |

Pitch |

4.5 |

5 |

5 |

5.5 |

5.5 |

6 |

|

|

|

|

|

|

|

|

b |

L≤125 |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

125<L≤200 |

102 |

108 |

116 |

- |

- |

- |

|

|

|

|

|

|

||

|

L>200 |

115 |

121 |

129 |

137 |

145 |

153 |

|

|

|

|

|

|

||

|

c |

max |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

min |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|

|

|

|

|

|

||

|

da |

max |

48.6 |

52.6 |

56.6 |

63 |

67 |

71 |

|

|

|

|

|

|

|

|

ds |

max=nominal size |

45 |

48 |

52 |

56 |

60 |

64 |

|

|

|

|

|

|

|

|

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Grade B |

min |

44.38 |

47.38 |

51.26 |

55.26 |

59.26 |

63.26 |

|

|

|

|

|

|

|

|

dw |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

64.7 |

69.45 |

74.2 |

78.66 |

83.41 |

88.16 |

|

|

|

|

|

|

|

|

e |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

76.95 |

82.6 |

88.25 |

93.56 |

99.21 |

104.86 |

|

|

|

|

|

|

|

|

L1 |

max |

8 |

10 |

10 |

12 |

12 |

13 |

|

|

|

|

|

|

|

|

k |

Nominal Size |

28 |

30 |

33 |

35 |

38 |

40 |

|

|

|

|

|

|

|

|

Grade A |

max |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

||

|

Grade B |

max |

28.42 |

30.42 |

33.5 |

35.5 |

38.5 |

40.5 |

|

|

|

|

|

|

|

|

min |

27.58 |

29.58 |

32.5 |

34.5 |

37.5 |

39.5 |

|

|

|

|

|

|

||

|

k1 |

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

Grade B |

min |

19.31 |

20.71 |

22.75 |

24.15 |

26.25 |

27.65 |

|

|

|

|

|

|

|

|

r |

min |

1.2 |

1.6 |

1.6 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

s |

max=nominal size |

70 |

75 |

80 |

85 |

90 |

95 |

|

|

|

|

|

|

|

|

Grade A |

min |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Grade B |

min |

68.1 |

73.1 |

78.1 |

82.8 |

87.8 |

92.8 |

|

|

|

|

|

|

|

|

Length of Thread b |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|||

Features and Benefits

DIN 6921 is a type of hex flange bolt that is commonly used in industrial and construction applications. This bolt has a flange that acts as a built-in washer and helps to distribute the load across a wider surface area. The head of the bolt is hexagonal in shape and is easy to tighten using a wrench or socket.

This bolt is widely used in machinery, automotive industries, and in construction, due to its exceptional strength and durability. It is made from high-quality materials such as stainless steel, titanium, and carbon steel, which provide long-term resistance against wear, corrosion, and rust.

DIN 6921 bolts are manufactured to tight tolerances and are subject to rigorous quality control measures to ensure that they meet the highest standards of quality and performance. These bolts are available in a range of sizes, lengths, and finishes to suit different applications and requirements.

In addition, DIN 6921 bolts adhere to strict industry standards, including DIN (Deutsches Institut für Normung) and ISO (International Organization for Standardization) standards. They are also tested for their hardness, tensile strength, and dimensional accuracy before being released for sale. All of these factors contribute to the superb quality and reliable performance of the DIN 6921 bolt.

Overall, the DIN 6921 bolt is a versatile and robust fastening solution that is used in many different industries. It is designed to provide excellent holding power, resistance to wear and tear, and ease of installation. Its high-quality construction and strict adherence to industry standards make it a top choice for engineers, designers, and construction professionals worldwide.